PyroTower

Next-generation pyrolysis system engineered for one purpose: reliable, low-emission biochar production anywhere on the planet.

Rugged simple, locally sourced system, cutting operational risk and unlocking truly scalable, decentralized carbon removal.

Key features

Thermo-catalytic methane scrubbing

Heat recovery in exchanger and hopper

Revolving floor for staged feed-in

Pre-fabricated build pack to ease transport

If you're interested in

buying a PyroTower

Pyrolysis

to lock carbon dioxide

Our model is to use pyrolysis to transform waste biomass into biochar. Pyrolysis is a technique of heating waste biomass at high temperature in a low oxygen environment. This essentially bakes the biomass turning the carbon into a type of coal (called intertinite). That is biochar.

High-efficient PyroTowers

built locally

We developed a novel pyrolysis system, the PyroTower that is just as good as industrial factories but x100 cheaper. This system can be locally constructed in just days (creating more jobs) and easily deployed to where crops are harvested or weeds are present, so waste biomass can be pyrolized on site.

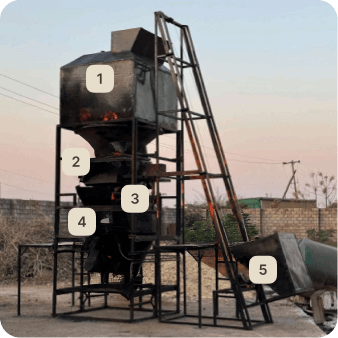

Main parts

Developed and scaled

in association with AgCinX

- Hopper

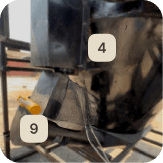

- Conical valves

- Blowers

- Reactor

- Buck elevator

- Rotating floor

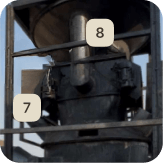

- Vibration engine

- Exhaust chimney

- Screen auger

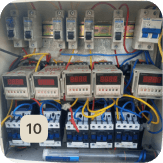

- Control box

Feedstock Flexibility That Eliminates Pre-Processing

Most pyrolysis systems fail where conditions are hardest: wet biomass, inconsistent feedstock, unreliable power, unskilled operators, rough terrain. PyroTower was built to eliminate these failure points — not by making the system complicated, but by making it smarter, tougher, and self-stabilizing.

At the core is a staged-flow reactor that delivers high thermal efficiency, low emissions, and stable combustion. This machine doesn't care about uneven ground, dust, heat, or rain.

PyroTower's airflow control and forced-air vortex enable clean combustion. Heat from the reactor and flue gas is recaptured to dry incoming biomass, reducing moisture and raising efficiency.

PyroTower is made from off-the-shelf materials and ships as modular blocks.

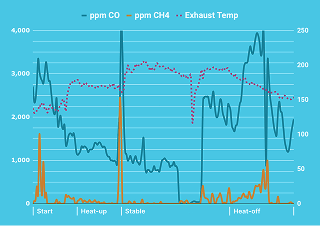

Emission Tests

Data from earlier design iteration

Emission Reduction Threshold at exhaust temperatures of 200 °C (easy to monitor)

Steady‑State Operation within 30 minutes and reaching 1.6 kg CH₄ per tonne

Reactor Mixing Sensitivity leads to transient emission spikes.

Bringing Carbon Markets to the Farmers Who've Been Shut Out

Most smallholder biochar producers cannot access carbon markets due to the lack of emissions control and sufficient MRV with artisanal production. Large industrial facilities meet standards, but they are centralized, capital-intensive, and do not operate where smallholder farmers live — meaning rural communities are excluded from both the technology and the revenue.

As a result, the majority of global carbon credit income flows to the Global North, bypassing the farmers who are most impacted by climate change. The PyroTower closes this gap: a clean-burning, mobile, mid-tech system that enables smallholder farmers to produce industrial-grade biochar with full digital MRV at a fraction of the cost.

Interested in PyroTower?

Contact usKon-tiki kiln

A worker focused solution that can be implemented anywhere

Even in the middle of nowhere which is the center of the world for our workers.

What is great about biochar is that in not only locks away the carbon for thousands of years it boosts crop yields.

Simple, yet effective

Kon-tiki kilns are used in remote areas for small productions. Any farmer can contribute to the planet health even without special equipment.